Home

Slide

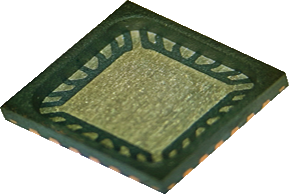

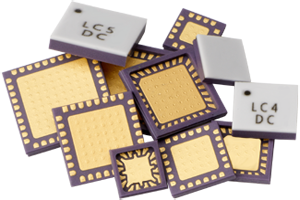

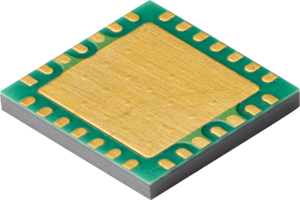

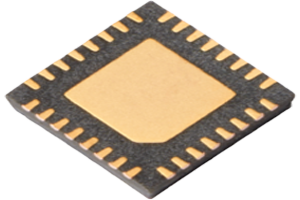

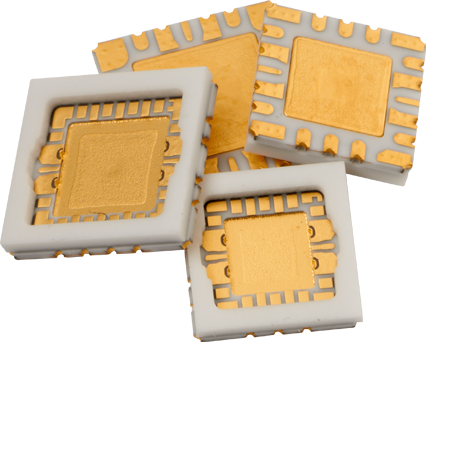

Integrated Circuit

Packaging

Packaging

Integrated Circuit

Packaging

Packaging

Low cost. High volume. Fully automated.

Low cost. High volume. Fully automated.

Integrated Circuit

Packaging

Packaging

Low cost. High volume. Fully automated.

Automation

Experts

By automating every step of the IC assembly process we work to increase reliability and drive costs down.

For each new product, we extend our stringent, ISO 9001 documented process to cover any new requirements and to ensure we build the products in the most efficient way. High quality and extremely high yield rates are a natural outcome of our manufacturing process.

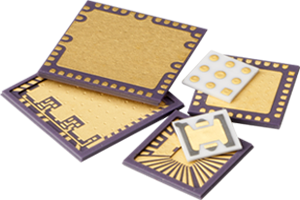

Mixed

Assembly Process

Combining a soldering process with our die attach and wire- bonding, allows low cost Surface mount passives to be placed inside the air cavity package.